How Does Changzhou Dingjia Metal Technology Co., Ltd. Ensure the Quality and Consistency of Stamping Parts?

In the ever-evolving landscape of precision manufacturing, delivering consistent quality is not merely an objective—it is an imperative. Changzhou Dingjia Metal Technology Co., Ltd., established in 2010, stands as a paragon of excellence in the realm of precision metal stamping. This privately-owned enterprise has meticulously crafted its reputation by combining cutting-edge design, rigorous quality control, and a commitment to innovation.

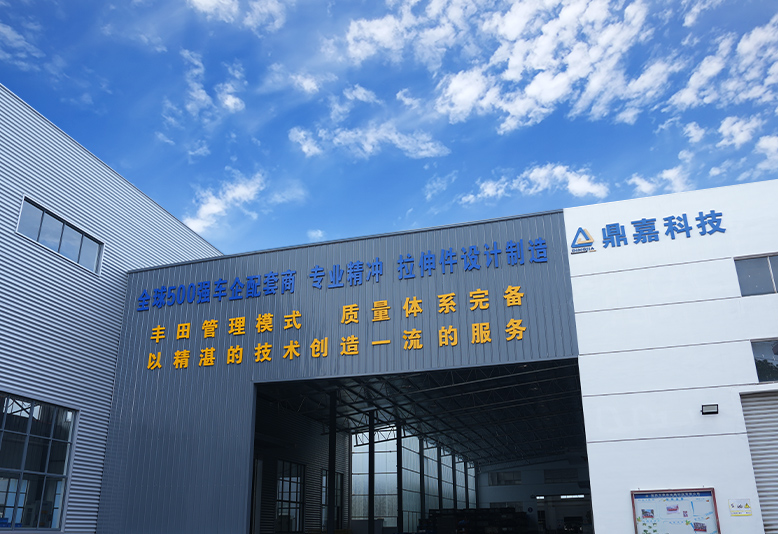

Situated in the strategic hub of Xueyan Town, Wujin District, Changzhou City, the company benefits from its proximity to major transport arteries, including Shanghai Pudong Airport and Changzhou Benniu International Airport. The 5,400 square meter facility, soon to be expanded by an additional 1,500 square meters, serves as a bastion of advanced manufacturing capabilities. With a registered capital of 19 million yuan, the company is well-positioned to scale operations while maintaining unwavering quality standards.

Precision in Design and Engineering

At the heart of Changzhou Dingjia’s process lies an intricate design and engineering phase. Every stamping part begins as a blueprint meticulously crafted to exacting specifications. The company’s in-house team of experienced engineers collaborates closely with clients to ensure that every dimension, tolerance, and functional requirement is accounted for. This foundational diligence prevents downstream errors, reduces waste, and sets the stage for flawless production runs.

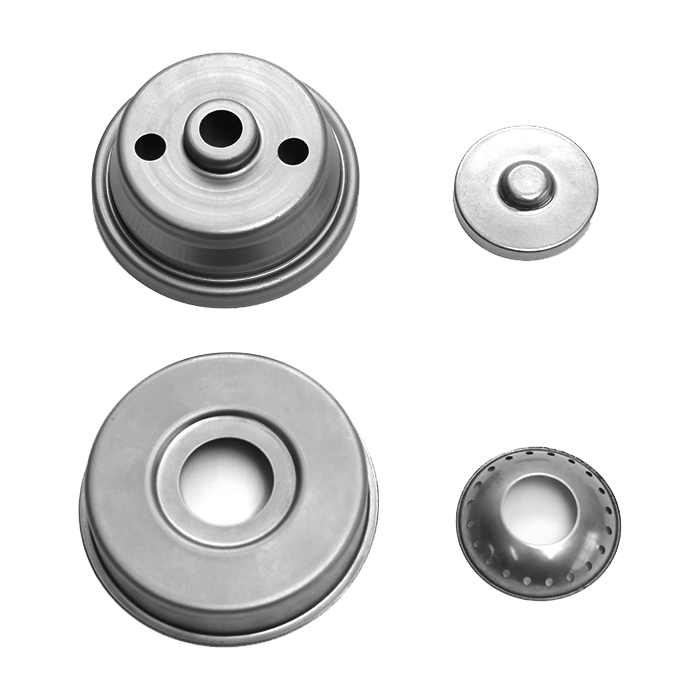

State-of-the-Art Manufacturing Processes

Changzhou Dingjia employs advanced metal stamping technologies, utilizing high-precision molds designed and assembled internally. This vertical integration allows for tight control over every stage of production, from initial forming to final finishing. By maintaining oversight of mold quality and maintenance, the company mitigates inconsistencies often caused by tool wear or improper setup.

Moreover, the adoption of automated machinery and real-time monitoring systems minimizes human error and enhances repeatability. Such automation is indispensable in sectors demanding stringent reliability, such as automotive, electronics, and medical machinery, all of which form the core clientele of Dingjia Metal.

Robust Quality Management System

A comprehensive quality management system underpins every operational facet at Changzhou Dingjia. The company adheres to rigorous inspection protocols, employing advanced metrology equipment to conduct dimensional verification and surface integrity assessments. Incoming materials undergo stringent testing to ensure compliance with exacting standards, thus establishing a dependable supply chain foundation.

Batch-to-batch consistency is guaranteed through Statistical Process Control (SPC), enabling early detection of deviations and swift corrective measures. Additionally, comprehensive documentation ensures traceability, vital for industries where compliance and accountability are paramount.

Commitment to Continuous Improvement

Quality is not a static achievement but a dynamic pursuit. Changzhou Dingjia embraces a philosophy of continuous improvement, regularly auditing processes and soliciting client feedback. This proactive approach fuels innovation, streamlines workflows, and elevates product standards.

The planned expansion of the manufacturing plant reflects the company’s commitment to growth aligned with quality assurance. Investments in new equipment and increased floor space will further empower Dingjia Metal to meet escalating demand without compromising precision or reliability.

Trusted Partnerships and Industry Recognition

Changzhou Dingjia Metal Technology Co., Ltd. has cultivated enduring relationships with many renowned enterprises, reflecting its credibility and consistent delivery. Its reputation for integrity and excellence is echoed across the automotive, electronics, and medical machinery sectors—fields where precision stamping parts must adhere to the highest benchmarks.

Changzhou Dingjia’s meticulous design processes, cutting-edge manufacturing, rigorous quality control, and unwavering dedication to continuous improvement coalesce to ensure the consistent quality of its stamping parts. This holistic approach transforms complex metal components into reliable building blocks, empowering clients to innovate and excel in their respective industries.